LIGHT, STRONG, DURABLE AND EASY TO PROCESS

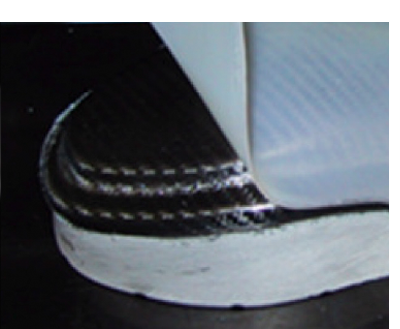

Duralite sheets are a thermoplastic matrix consisting of multiple materials that together create a light, strong, durable and easy to process material. Duralite is already slightly deformable at a temperature of 100°C. By heating the Duralite material to a temperature of 210 to 230°C it becomes fully deformable. It is important that Duralite is processed within 15 to a maximum of 30 seconds once it is in an activated state. This causes the fiber layers to melt together so the structure becomes firmer and its original stiffness is increased. After cooling the shaped sheet it recovers its original aesthetic appearance.

The three ways to shape Duralite sheets and components

- Using a press Within a few seconds, place the activated plate (210-230ºC) in the preheated press (175ºC). Press the sheet material for 20 seconds at an applied pressure of approximately 6 bar. In this time the temperature is reduced to approximately 60° C, so the material cools down and retains the required shape. This way of shaping is ideal for batch production.

- Using a Vacutherm machine Probably the most-used method. Applicable to all thickness versions and compositions. To prevent adhesion, the component needs to be placed between two layers of silicone. Sufficient pressure is essential to obtain a stable and homogeneous final result.

- Using an industrial dryer Post-processing is easy by reactivating the material locally using an industrial hot air blower.

The fiber layers in a sheet of Duralite are woven at an angle of 45 degrees. Therefore components may be processed in both the longitudinal and transverse direction of a sheet. To attain the required stiffness with minimal torsion diagonal processing is not recommended.

Carbon and glass fiber sheets can be cut in several ways

- Sawing with a band saw is possible though with a risk of rough edges.

- Snipping and/or die cutting works for straight lines, is the standard method for panels and ideal for thin panels up to 0.75 mm thick.

- Waterjet cutting is extremely precise, smooth, clean edges and the recommended way.

- Punching is efficient for larger batches, not recommended for sheets over 1.5 mm thick.

Duralite composites are easy to weld and glue. We can provide you with tailored advice on this. When processing, take the necessary safety precautions into account. Protect eyes and hands.

Duralite® is an innovation of

Frecoma

Ordelven 9

5056 DC Berkel-Enschot

Netherlands

Phone +31 (0) 13 511 50 00

To contact form